Patent Application Filed. Title: Vehicle Active Aerodynamics and Dynamics Control via Flow Vectoring

💡 What It Is

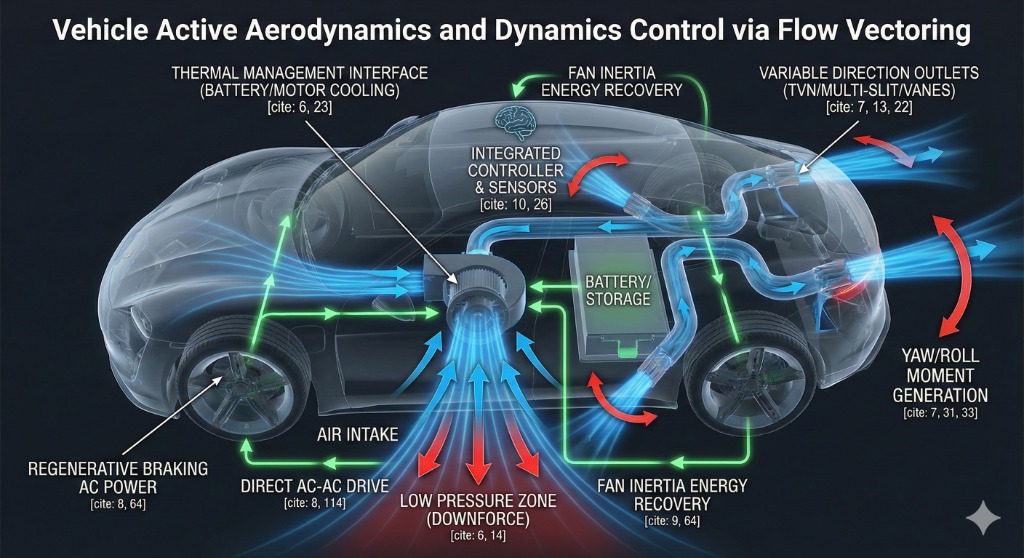

Active Aero Flow Vectoring is an integrated vehicle dynamics system that goes beyond simple “fan car” downforce. It uses underbody gas transport devices (fans, blowers, or compressors) to suck air from beneath the vehicle to create massive downforce.

Crucially, instead of simply expelling this air, the system utilizes Thrust Vectoring Nozzles (TVN) or Multi-Slit Selectors to actively steer the discharge airflow. This generates control moments (Yaw, Roll, Pitch) to stabilize the car or enhance cornering agility, effectively using air as a control surface.

⚠️ The Problem

Traditional aerodynamic devices (wings, spoilers) rely on vehicle speed to work and are generally passive.

- Limited Low-Speed Grip: Conventional aero generates little downforce at low speeds.

- Lack of Integration: Previous “fan downforce” concepts focused solely on vertical grip and lacked integration with the vehicle’s energy management or thermal systems.

- Energy Waste: Standard systems do not recover the kinetic energy of the spinning fans or utilize regenerative braking power efficiently.

🛠️ The Solution: Suck, Vector, and Recuperate

This invention combines fluid dynamics with advanced power electronics to create a holistic control system.

1. Flow Vectoring & Dynamics Control

The system sucks air to create a low-pressure area ($\Delta p^*$) under the chassis or inside a plenum. This air is then ejected through a Directional Variable Discharge Unit:

- Thrust Vectoring: The discharge direction, area, and flow rate are dynamically controlled (Front/Rear/Left/Right/Up/Down).

- Vehicle Control: By creating asymmetric thrust, the system generates Yaw (for turning), Roll (for stability), and Drag (for braking) moments independent of tire grip.

2. Direct AC-AC Regenerative Drive

The system drives the aero fans using Regenerative Braking Power through versatile power topologies:

- Matrix Converter: Connects the traction motor’s AC regeneration directly to the fan motor via synchronous switching, minimizing conversion losses.

- Flexible Power Topology: Supports both direct AC-AC conversion (Matrix Converter) and conventional DC-Link topology, allowing for versatile integration depending on vehicle architecture.

- Smart Energy Management: If the battery cannot accept high-current regen (due to full SOC or temperature), the excess power is instantly diverted to the fans to generate braking downforce.

3. Inertial Energy Recovery (“Virtual Flywheel”)

The high-speed fans act as a mechanical battery. When the fans need to slow down, the system switches to Generator Mode, harvesting the rotational inertia of the fans back into electrical energy to feed the traction motors or battery.

4. Thermal Integration

The intake air doesn’t just generate downforce; it can be routed through Heat Exchangers (Radiators for Battery/Motor/Inverter) before being discharged, providing massive cooling airflow during high-load driving.

⚙️ Operation Modes (Logic)

The system adapts to real-time driving conditions using sensor fusion and predictive control.

| Scenario | System Action |

|---|---|

| Corner Entry | Uses surplus regenerative power to spin up fans. Generates max downforce and vectors exhaust inward to assist yaw (turn-in). |

| Corner Exit | Recovers fan energy (slow down) to boost acceleration. Vectors exhaust rearward to reduce drag and maintain rear grip. |

| High Speed / Crosswind | Uses asymmetric Left/Right vectoring to counteract side winds and stabilize yaw. |

| Active Drag | Vectors airflow forward or restricts discharge area to generate maximum aerodynamic drag for braking. |

🏗️ Key Components

- Gas Transport Device: Fans, blowers, or compressors (single or distributed array).

- Variable Geometry: Active skirts, plenum chambers, and diffusers that adjust sealing and volume.

- Valve Assembly: Includes electronic flaps and Tesla Valves (no-moving-part check valves) to prevent backflow.

- Vectoring Nozzles: TVN (Thrust Vectoring Nozzles), Multi-slit selectors, or Synthetic Jets.

📜 Patent Claims Summary

This patent application covers:

- The System: A device combining underbody suction with multi-directional discharge vectoring (TVN/Multi-slit).

- Power Topology: A power conversion method that applies regenerative AC power directly to fan motors via synchronous switching or matrix converters.

- Energy Recovery: A method to recover fan inertial energy back to the vehicle’s drive system.

- Control Method: A logic that integrates thermal management, active aero, and ESC/Torque Vectoring into a single multi-objective optimization loop.